Aerobraze Engineered Technologies Cincinnati provides a variety of advanced manufacturing services from their facility in Cincinnati Ohio. Aerobraze Cincinnati processes over 100 unique shop orders every month ranging from heat treat processes to complex machining-assembly-braze-NDT operations.

Services provided include brazing, heat treatment, assembly, CNC machining, coatings, welding and non-destructive testing (X-ray & FPI). Aerobraze Cincinnati manufactures high quality products & provides manufacturing solutions for aerospace, defense, power generation, oil & gas, and other industrial clients.

- 90,000 sq. ft. facility with room for expansion

- Quality certifications in AS9100, ISO 9001 and several Nadcap special processes

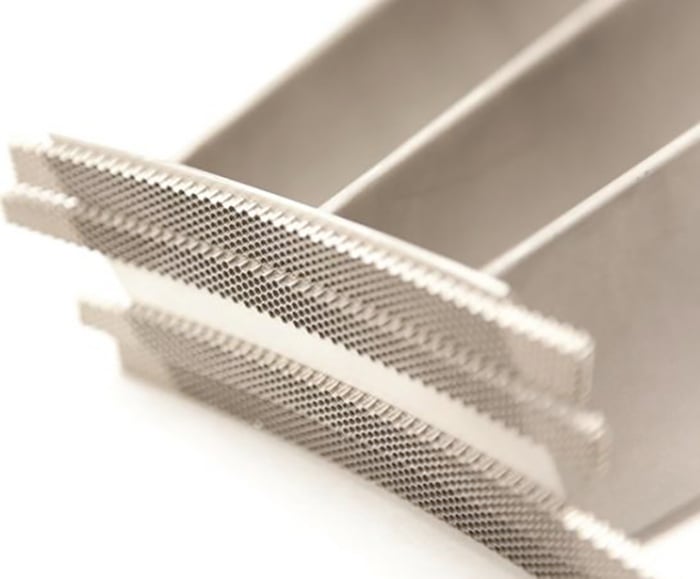

- Over 100 diverse shop orders every month - turbine engine components, honeycomb seals & segments, heat shields, and turbomachinery parts

- Brazing & Heat Treatment - High-temperature Vacuum Brazing and Heat Treatment, Hydrogen Atmosphere Brazing, Hydrogen and Argon Furnace Brazing, Torch Brazing, Honeycomb Powder Sintering

- Advanced assembly

- CNC Machining: Horizontal and vertical 3 & 4 axis milling, Large part vertical turning, Traditional CNC turning

- Coatings

- Welding / Joining - GTAW (TIG) Welding, Longitudinal TIG Welding, Resistance Welding, Precision Welding, (TIG) Fusion Welding

- Quality Inspection – NonDestructive Testing (NDT) including X-Ray, Fluorescent Penetrant Inspection (FPI) and CMM Inspection

Diffuser Assembly from Aerobraze Cincinnati

Find out more about Aerobraze Cincinnati

CONTACT

940 Redna Terrace | Cincinnati, OH 45215

E: aet@wallcolmonoy.com

T: 513-842-4200