OEM and Aftermarket

Turbine Engine Components

Aerobraze Engineered Technologies - Cincinnati, a division of Wall Colmonoy, specializes in the complete manufacture and repair of turbine engine components. Aerobraze Cincinnati has more than 60 years of experience supporting major turbine engine OEMs as a Tier 1 Supplier. Turbine engine components include turbine nozzles, guide vanes, blades, diffusers, vane segments and seals.

Turbine engine components are produced through the processes of vacuum brazing, heat treatment, welding, thermal spraying and machining. All turbine engine components are quality inspected. Aerobraze Cincinnati can also provide NonDestructive Testing (NDT), X-Ray, Fluorescent Penetrant Inspection (FPI), Magnetic Particle Imaging (MPI) and CMM Inspection.

Aerobraze Cincinnati has Nadcap certifications in Brazing & Heat Treating, Coatings, Welding, and NonDestructive Testing (NDT). It is also AS9100 / ISO 9001 certified and a FAA-Approved Repair Station.

- Design, Engineer, Manufacture & Repair:

- Turbine Nozzles

- Turbine Guide Vanes

- Turbine Blades

- Turbine Engine Compressor Diffusers

- Turbine Vane Segments

- Turbine Vane Seal Tab Assembly

- Honeycomb Seals and Segments

- Brackets

- Diaphragms

- Titanium Thrust Links

- Processes:

- Brazing, Heat Treating

- Assembly

- Machining

- Welding/ Joining

- Coatings

- Quality Inspection

- Non-destructive testing (NDT)

- Chemical Processing / Cleaning

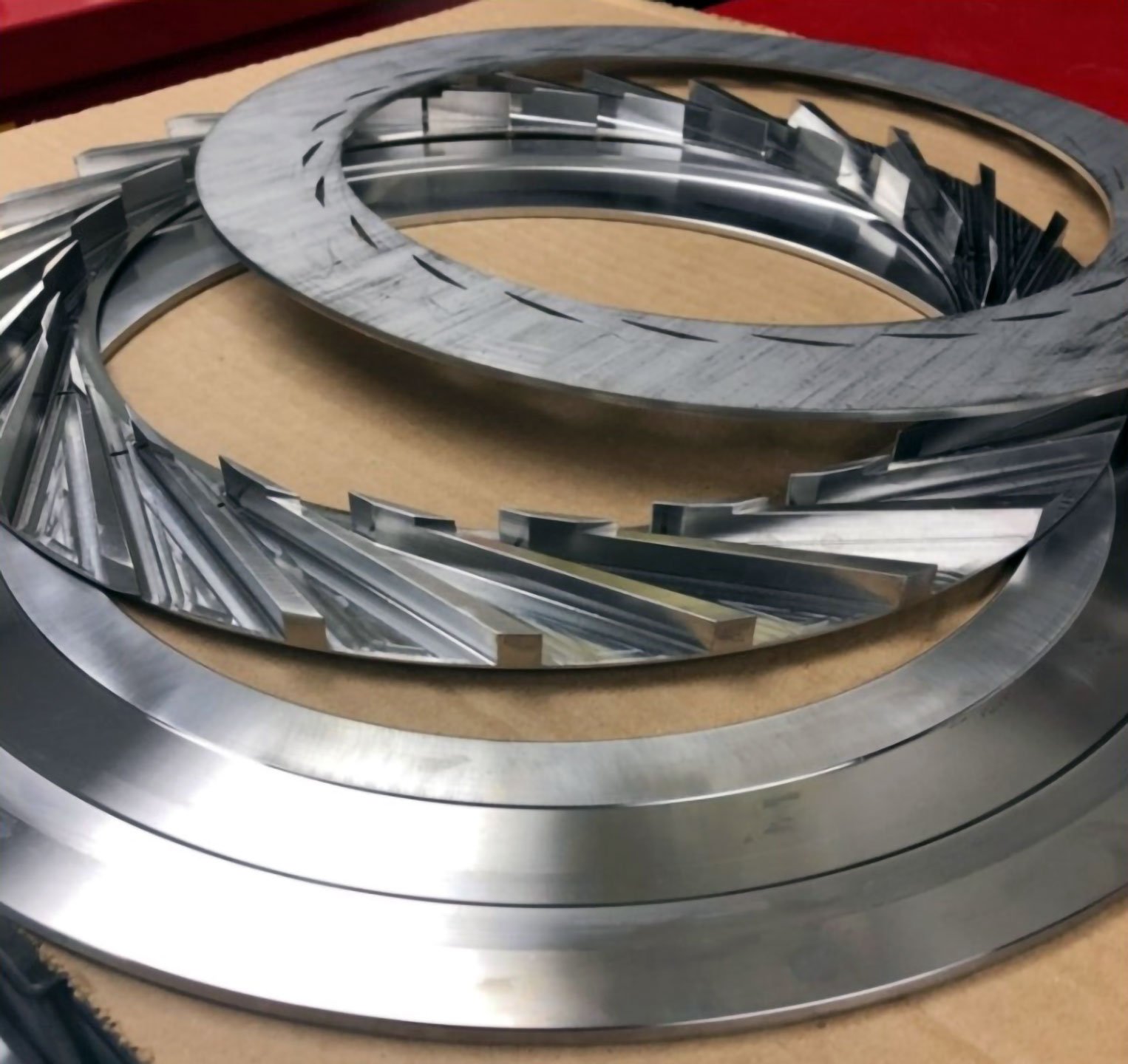

Turbine Nozzles – Weld, Assembly, Braze, Heat Treat, Machined

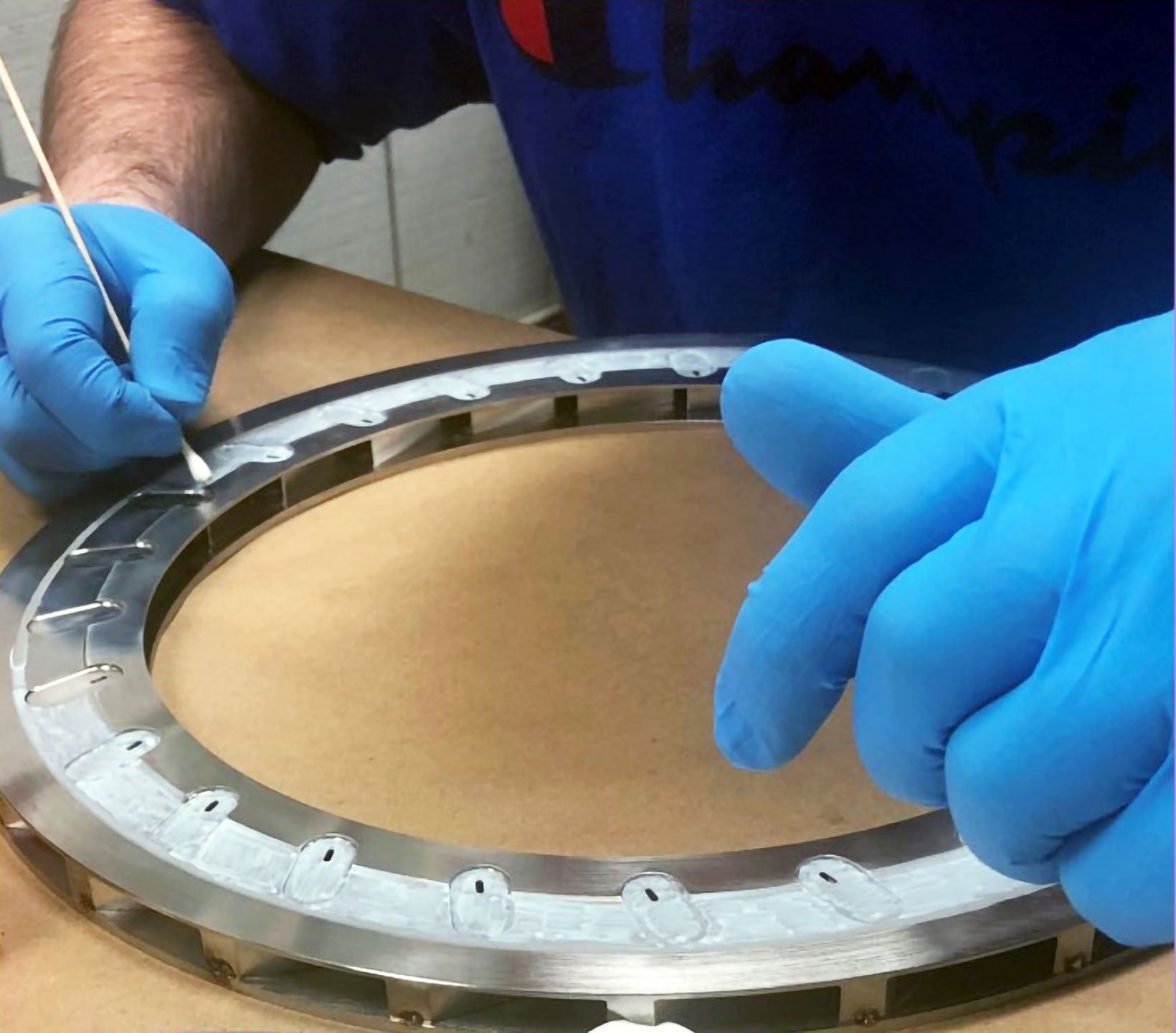

Inspecting a Turbine Nozzle Assembly

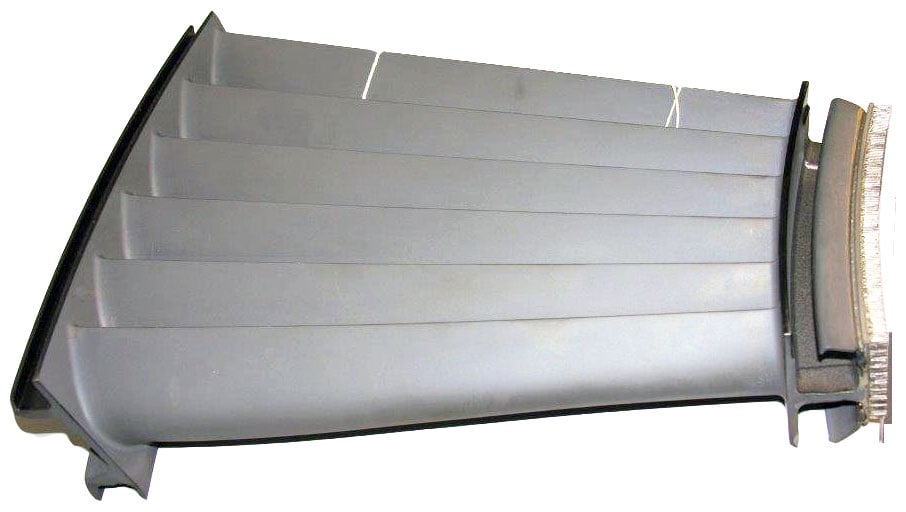

Helicopter Engine Diffusers – Fabricated Complete

Turbine Engine Diffuser – Assembled and Brazed

Turbine Vanes - Welded and Torched Brazed

Turbine Vane Segment - Assemble, Brazed, Heat Treated

Machining

We offer a full range of machining capabilities for fast flexible turnaround to meet exact customer specifications.

Turning

- CNC Horizontal Lathe (2-Axis) x 4

- CNC Vertical Lathe (2-Axis)

Milling

- CNC Vertical Mill (3-Axis) x2

- CNC Horizontal Mill (5-Axis)

For complete list, visit Machining page.

Machining turbine diffusers

Download the flyer here

CONTACT

Cincinnati

940 Redna Terrace | Cincinnati, OH 45215

E: aet@wallcolmonoy.com

T: 513-842-4200